Lizard AC Field Measurement Probes

"Provides a far superior view of any defects compared to normal non-destructive testing" - Project Manager Rail Overhaul Project USA

The standard range of LIZARD probe types are designed to suit most industrial applications and common weld geometry found within many engineering structures with most probe types available as either topside or subsea variants. Typically LIZARD probe types are supplied as arrays with Absolute (Bx) and Current Perturbation (Bz) per channel, arranged in pairs. In this way the LIZARD allows the user to obtain data sets from a single sweep that encompasses defect location, defect depth and length information, lift off/probe coupling and Classic impedance information from both Absolute (Bx) and Current Perturbation (Bz) components in a user friendly display (Note - Lift Off is a term that describes the distance between the active probe and the conductive surface of the test piece probe coupling).

Due to the unique LIZARD interrogating technology the user is able to apply adjustments to the raw or processed data to improve scan clarity by reducing the effect of Lift Off (probe handling minimisation) and defect display optimisation using phase positioning, all by way of simple software sliders or numeric input using the powerful Lizard Adjustments menu within the software suite. Lizard probe types are generally multi-frequency operational and therefore the same sensor type can be used at differing frequency ranges to enable inspection of most ferrous and non-ferrous inspection applications.

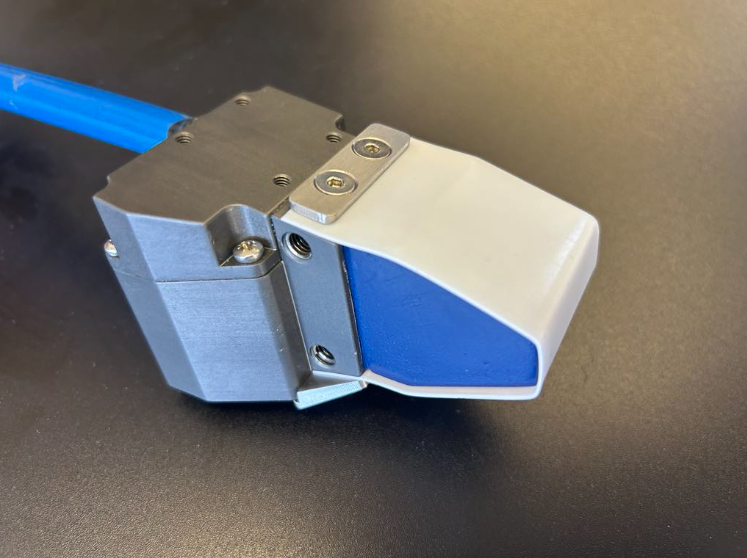

The LIZARD probe range are generally housed in a hard anodised aluminium body housing with super hard encapsulate for sensor protection. Due to the available ‘Lift Off’ properties of the LIZARD probe types additional protection can be given to the probe face without compromising inspection integrity, this since the Lizard interrogation technology is non-contacting. Additionally this ‘Lift Off’ can also be utilised for inspection through non-conductive coatings (such as paint, epoxy coatings) or conductive coatings (such as flame sprayed aluminium, zinc) whilst also providing positional feedback for complex operations such as robotically deployed methods of inspection.

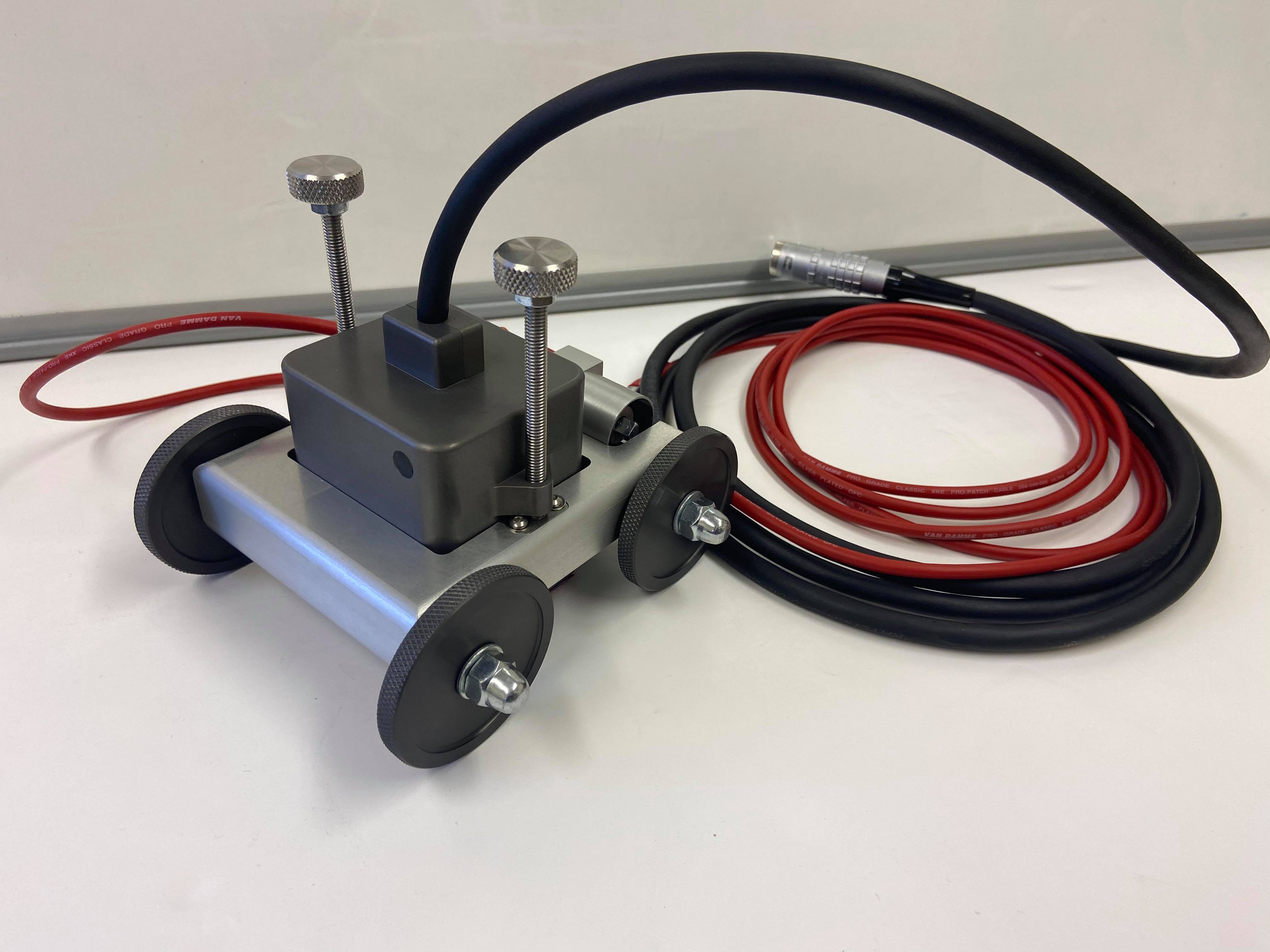

Due to the unique process used by the LIZARD software for defect measurement, encoder devices are not generally required and therefore structures still having grime, grease or other residual coatings, can easily be inspected without the usual concerns or cleanliness required for mechanical or optical encoders. Should the application require an encoder the LIZARD M8 XL system can provide support by simple connection to the Remote port.

LP100T

Compact probe for precision testing.

LP600T

High sensitivity probe for detailed analysis.

LP610T

Versatile probe with extended range.

LP801T

Enhanced probe for industrial applications.

LP833T

Superior accuracy for non-destructive testing.

LP184T

Reliable probe for multi-purpose use.