Speciality Probes

As is often the case in our industry, a need arises that cannot be adequately addressed with standard off the shelf NDT products. In these situations Lizard® has a proven track record of supplying custom built sensors, software and systems, to fit the need of the client quickly, to budget, and most importantly meet the application specification with a successful working end product. Some examples of previous custom built probes are shown below.

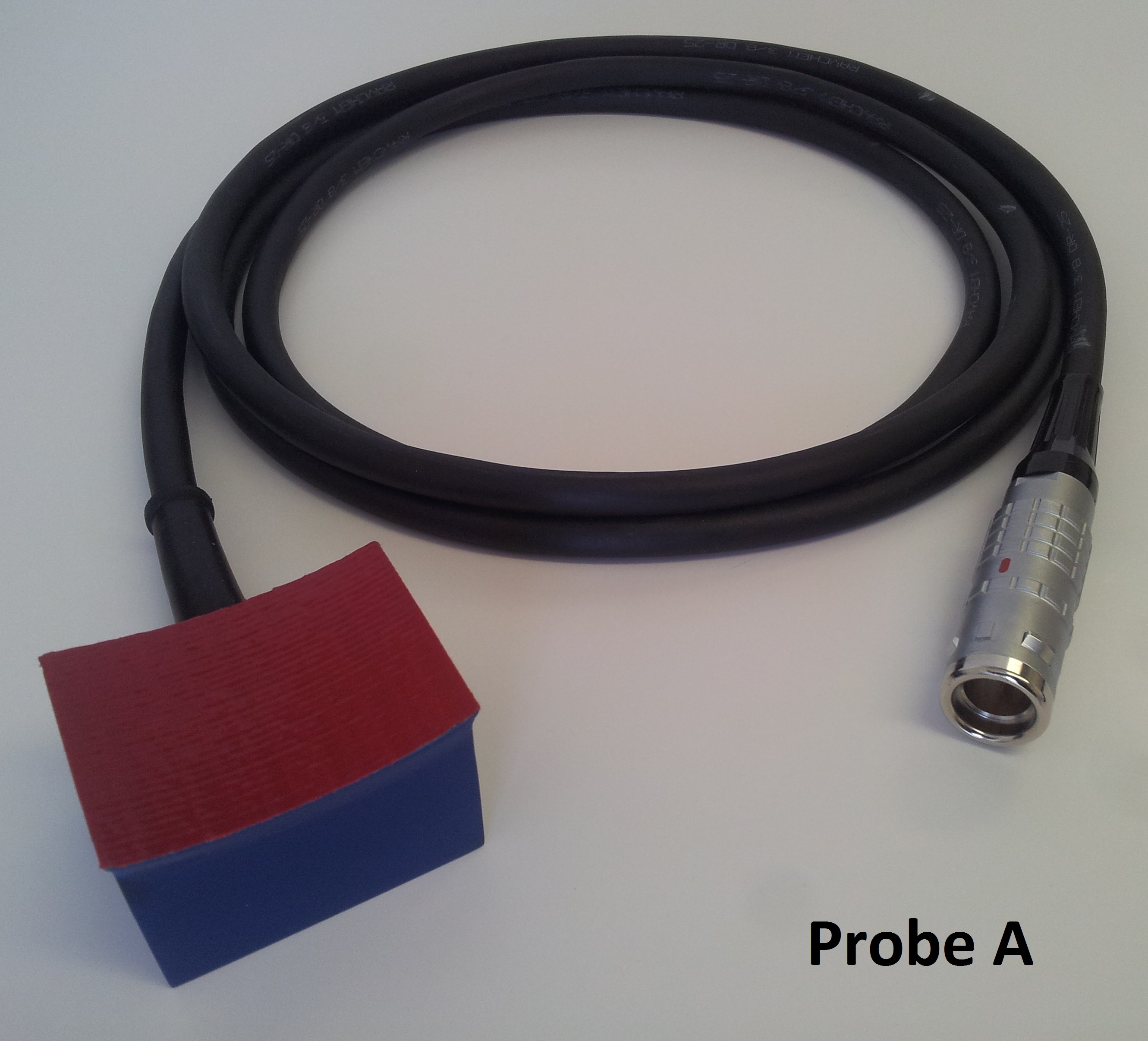

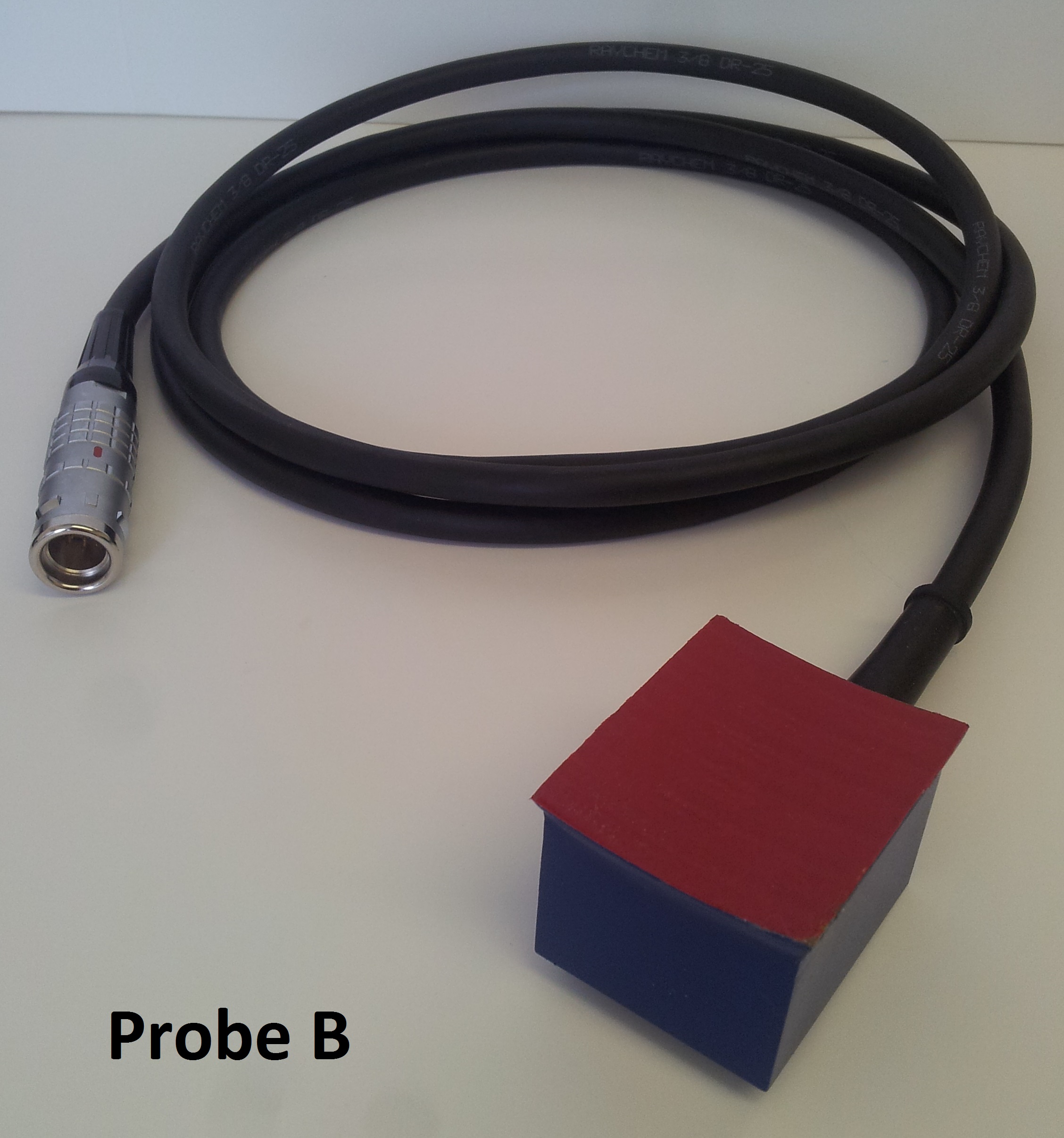

Wind farm

These Lizard custom probes were designed to be used in the wind farm industry for scanning 15cm diameter securing bolts. Probe A is for vertical direction scanning and Probe B is for horizontal direction scans. These same style probes could be used on a large variety of cylindrical/tubular structures. Omni-directional versions of these probes are also available if the application supports the use.

These Lizard custom probes were designed to be used in the wind farm industry for scanning 15cm diameter securing bolts. Probe A is for vertical direction scanning and Probe B is for horizontal direction scans. These same style probes could be used on a large variety of cylindrical/tubular structures. Omni-directional versions of these probes are also available if the application supports the use.

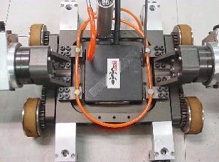

Rail

This probe was designed for the rail industry to scan for radial or tangential cracks on the surface area around 12mm nominal holes. The holes could only be accessed from one side with limited access, requiring a compact automated probe assembly. The head of the probe is fitted with three expanding fingers that centralize and hold the probe in place. This minimizes the size of the probe yet allows the scanning to be automated via a motor that is directly controlled by the host unit to provide a synchronized scan, allowing the system to be used by a single operator. Degree markers on the scan indicate the position of any defects.

This probe was designed for the rail industry to scan for radial or tangential cracks on the surface area around 12mm nominal holes. The holes could only be accessed from one side with limited access, requiring a compact automated probe assembly. The head of the probe is fitted with three expanding fingers that centralize and hold the probe in place. This minimizes the size of the probe yet allows the scanning to be automated via a motor that is directly controlled by the host unit to provide a synchronized scan, allowing the system to be used by a single operator. Degree markers on the scan indicate the position of any defects.

LPG Tanks

This Lizard system has been automated for inspecting inner cracking of LPG tanks under robotic control. Expoxy layers are applied on the inner tank surface to alleviate stress corrosion cracking which, without the Lizard system, would require removal before any inspection. The system shown here is a remote scanner with magnetic rollers carrying automated Lizard Field Gradient Imaging tracked using a video camera. The system is able to provide crack detection down to 10mm in length by 1mm depth and assures full coverage of the inspection area.

This Lizard system has been automated for inspecting inner cracking of LPG tanks under robotic control. Expoxy layers are applied on the inner tank surface to alleviate stress corrosion cracking which, without the Lizard system, would require removal before any inspection. The system shown here is a remote scanner with magnetic rollers carrying automated Lizard Field Gradient Imaging tracked using a video camera. The system is able to provide crack detection down to 10mm in length by 1mm depth and assures full coverage of the inspection area.

Connect With Us

Contact Us Today For More Info - +44 (0)23 92252642